Access to GPS-equipped technologies have exploded in the turfgrass management industry over the past decade. These technologies monitor soil moisture, measure turf health, and improve application precision. The rise of GPS-enabled sprayers offer the potential to significantly improve management precision, but are these technologies worth the upfront cost? What’s the learning curve to implement these new tools at your facility? What’s the return on investment? How can the new GreenKeeper CIS help manage these technologies? Here are some ways to save money and improve turfgrass health with GPS-enabled sprayers, crop sensors, and new methods of pest scouting.

Rise of GPS-enabled Sprayers in Golf and Sports Turf

GPS-enabled sprayers with individual nozzle control improve application precision by eliminating excessive overspray and sprayer overlap. The operators can see skips between passes and the sprayer’s controller can shut off individual nozzles to minimize overlap. This level of automation and awareness allows sprayer operators to increase the sprayer speed from 2-4 MPH up to 6-10 MPH. It also allows applications to be made in complete darkness ahead of nightly irrigation. This reduces labor costs, keeps the sprayer safely ahead of golfers, and helps improve the efficiency of “watered-in” applications.

Benefits of Individual Nozzle Control

Individual nozzle control also saves product and money because it reduces the amount of mix required to treat an area. Nozzles promptly turn off and on as the sprayer exits and enters the treatment area. For example, the putting greens at Jim Ager Jr. Golf Course, a nine-hole par three course in Lincoln, NE, are approximately 40,000 SQFT. When using a traditional sprayer with an experienced operator, 55,000 SQFT of mix are required to treat the greens and the surrounds. The individual nozzle control reduces overspray beyond the green perimeter and eliminates excessive overlap between passes. As a result, we typically mix to treat 40,000 SQFT which reduces product requirements and filling/mixing time by roughly 25%. Pair that with a faster sprayer speed and the cost savings are substantial.

Dr. Rossi’s team at Cornell University completed a case study in 2018 at Skaneatles Country Club that compared GPS-assisted application with the Frost system to a conventional sprayer system. Fairway acreage was reduced from 29 acres to 24 acres with the aid of the GPS system – 17% savings. When compounded across all the applications within that season, 71 total acres of mix were eliminated, and 446 lbs. of pesticide active ingredient were withheld from the environment. Labor required to both mix and treat was reduced by 75%. Their return-on-investment period was less than two seasons.

Precent Savings versus Area Savings

The amount of product/time saved really depends on a few different factors. They include the experience of the operator, size and shape of the area being treated, and the presence of auto-steer on the sprayer platform. Most sprayer manufacturers and distributors cite a product savings of 8-20%, but the percentage saved is NOT always the best metric to sell a GPS sprayer to your GM, owner, or board of directors.

Smaller sized areas (Ager GC greens, tees, and collars) have larger percentage savings because of their small perimeter size and complex perimeter shape. That’s why we could reduce the product requirements by 25% with individual nozzle control; 15,000 SQFT saved. On the other hand, the fairways are larger (200,000 SQFT) with a more rectangular shape. We mix for 200,000 SQFT with the Frost GPS-sprayer compared to 225,000 SQFT with a “dumb” sprayer. That only saves 11%, but it’s over a larger area. Extrapolate an 11% savings to a course with 40 acres of fairway, and the savings is substantial (4.4 acres of product saved)! It can be helpful to describe the saving in aggregate when campaigning for a new GPS sprayer. For example, “We can save 20% on each greens spray – the most frequently treated area of our course, and we can save $15,000 on from the chemical and fertilizer budget.”

Non-fiscal Benefits of Individual Nozzle Control

There are other benefits to individual nozzle control that are equally important – or more important in my opinion – than the product savings. These are also important selling point for the technology.

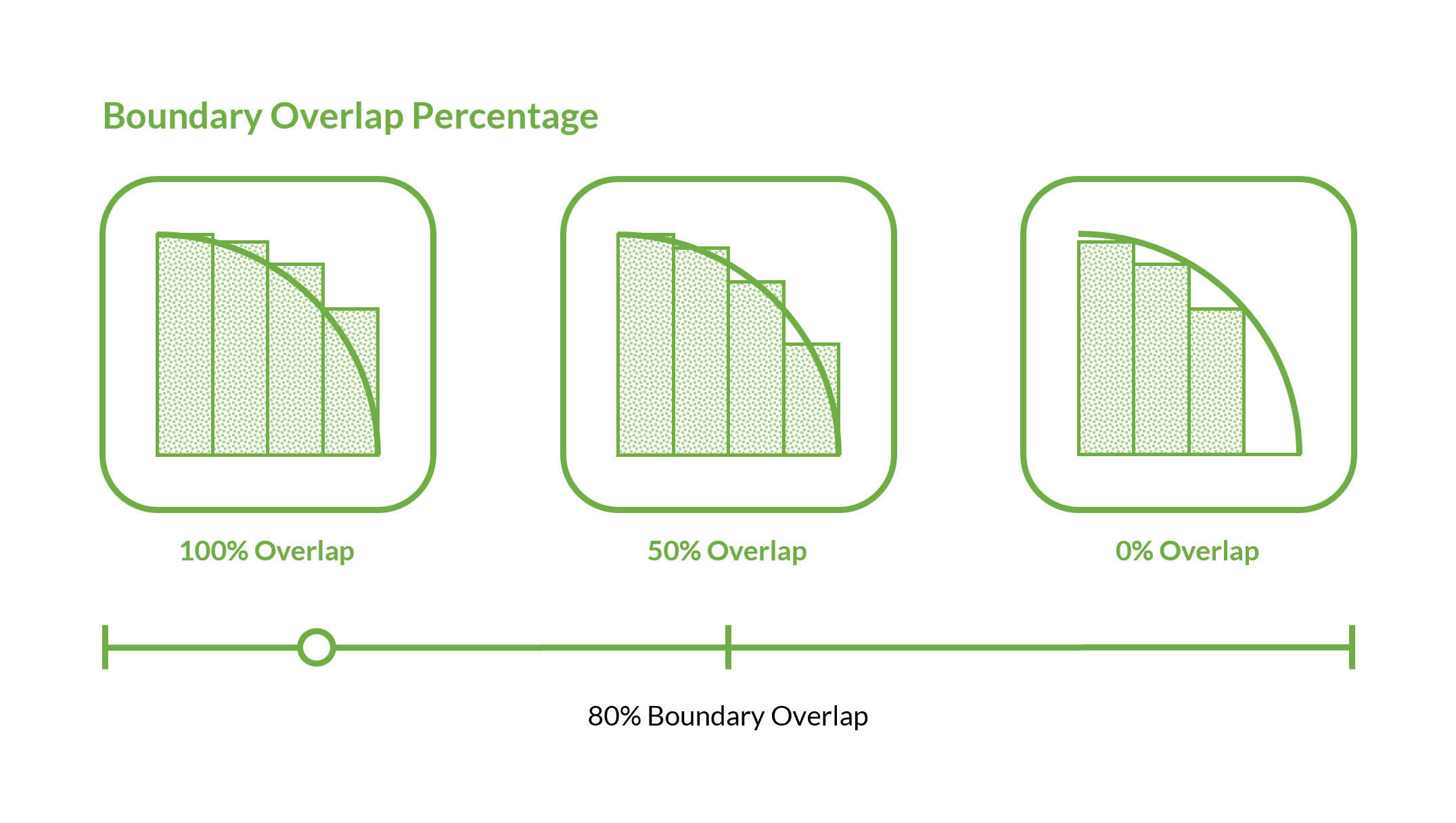

We’ve shown that golf course collar decline is frequently the result of PGR over-spray from greens apps on the collars. PGRs last longer and suppress more growth at collar height turf than greens height turf, especially on cool-season species. The frequent greens apps can quickly cause 70-90% clipping yield suppression on collars. The addition on small amounts of stress under this level of growth suppression can quickly become lethal.

We configure our sprayer to have 0% perimeter overlap when spraying greens. The nozzles turn off before the PGR application touches collar height turf. The perimeter overlap is then changed to 100% when treating collars, fairways, and approaches. The collar overspray covers any skips on the putting green cleanup. This small change has significantly improved the health of the bentgrass collars with no negative effects on the clean-up pass of the greens. We can also target nitrogen fertilizer applications to the collars when they are starting to feel the effects of summer stress and traffic.

Draw and Adjust Perimeter Boundaries with GreenKeeper CIS.

Software is required to precisely adjust course boundaries to maximize the benefits of GPS-enabled sprayers. For example, sprayer operators notice a green boundary is shifted 10” south or a nozzle stayed on into the collar. To the frustration of many GPS-sprayer operators, including me, was not any easy-to-use software programs to make these adjustments. Then I remembered that I operate a turf management software company.

GreenKeeper App’s CIS (Course Information System) was designed and built to address many of the challenges that I had controlling the GPS-sprayer at Ager Golf Course. Users can draw and adjust course boundaries on the fly, crop areas like bunkers from fairways and collars, map pest locations, and create custom sprayer maps. Select the target areas, set the sprayer output (i.e. 80 gallons per acre) and generate a prescription application map. Yes, the exported shape-files are compatible with all the turf sprayer systems available in the turf market.

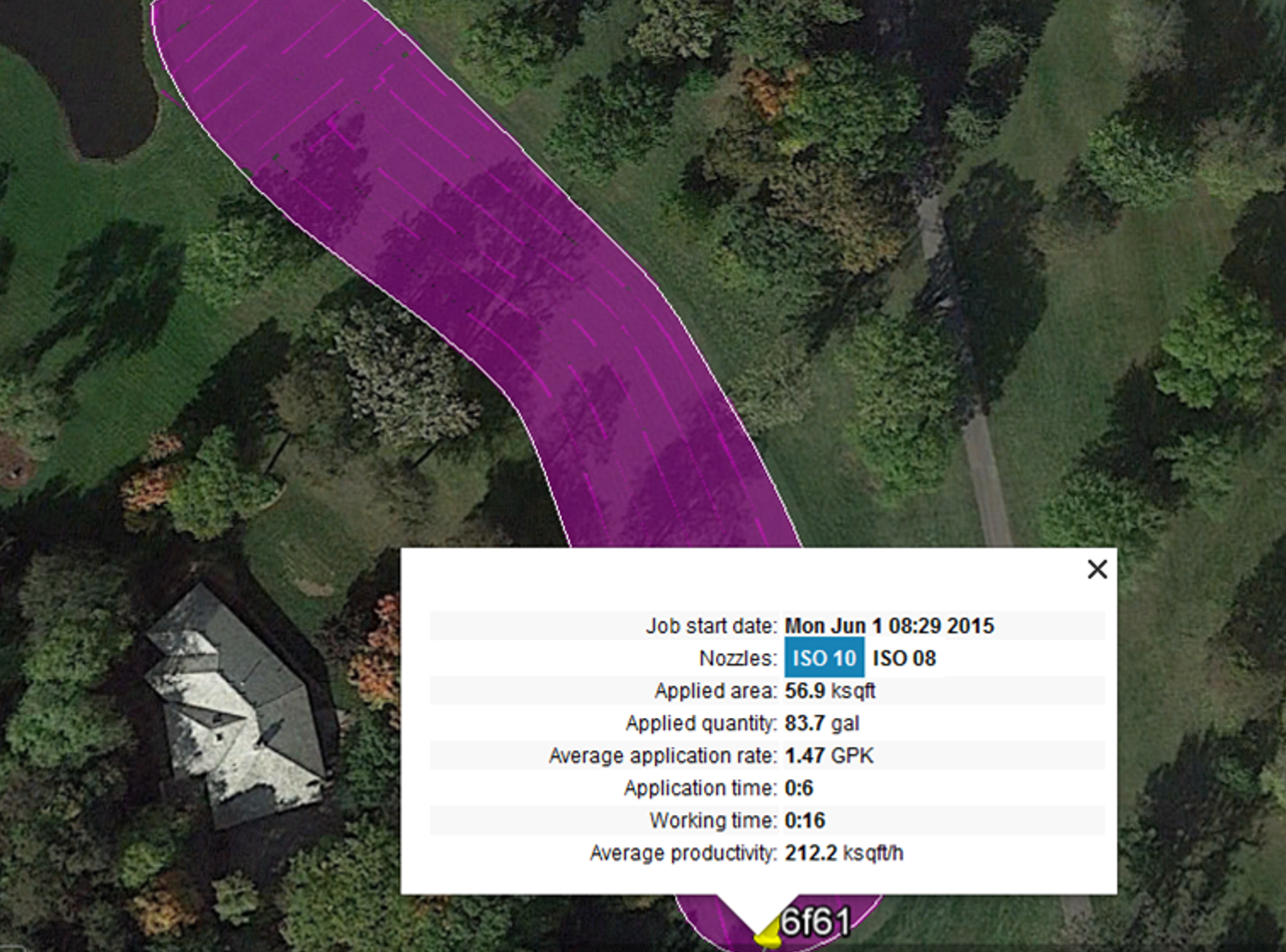

Post-Application Reporting Capabilities

All GPS-enabled sprayers also provide detailed maps of past applications. Additional application/job data can include start/end time, total acreage treated, the amount of mix applied, and even the productivity of the operator (square feet per hour). These reports are great for scouting skips and can be linked to application records within GreenKeeper App (product rates, weather, applicator name). It can be hard to assign a dollar amount to these “non-fiscal” benefits, but I value that peace of mind over the product savings.

Turn those POST- Apps into PRE- Apps

Yellow nutsedge is a troublesome perennial pest at Ager Golf Course. Products like Sedgehammer (halosulfuron) are most effective when nutsedge is starting to emerge in spring (mid-May in Nebraska). However, it can be difficult to locate those emerging weeds during that time of year. It would be easy to simply spray the entire course, wall-to-wall, but that would use more product and labor than targeting specific areas.

With GreenKeeper CIS, I reviewed prior curative Sedgehammer applications from past summers to draw pest control boundaries early (PRE) applications in May. This reduced the total area treated from 20+ acres to less than four acres. This approach also works well for other pests like crabgrass and goosegrass. Target areas that had breakthrough last summer with a sequential PRE app to increase the likelihood of season-long control.

Map and Photograph Pests in the Field

I drive myself crazy when trying to spot treat pests during the summer? I’ll load up the sprayer and then tax my brain to remember all the different pest locations. Inevitably I’ll forget spots and need to try again later. In the past I would shade pest locations on a scorecard with a marker. Every pest had a different scorecard.

GreenKeeper CIS has simplified mapping. I can now map pests as I’m driving around or mowing. I can even see my GPS location on the CIS maps to draw circles and other polygons. Here’s a real example of how I used this feature last August.

We started to get Pythium root rot on the Ager greens at the end of August. When replacing the flagstick after mowing, I would walk the green and highlighted weak-looking areas in GreenKeeper CIS. After I was done, GreenKeeper CIS told me the five locations totaled only 5,600 square feet. I washed up the mower and loaded up the Frost VRT sprayer with Segway and Simplot’s CounterAct Firm wetting agent to precisely treat those areas. I mixed enough to product to treat 7,000 square feet (15 gallons) and made the application in a few minutes. Normally I would have mixed to treat 90,000 square feet, a product savings of 92% plus an hour of labor. The locations quickly recovered over the next week.

Aid Scouting with Sensors and Machine-Learning

Our research group has been studying different imagery technologies and crop sensors systems to identify and geolocate pests. This is a larger topic that I’ll save for later this winter. The upside of these technologies is great, but the require significant training to maximize that potential. We have shown that crop sensors pair with variable rate technology sprayers reduced nitrogen fertilizer requirements by 80% on the Ager fairways. The Holland Scientific crop sensor systems now stream data right into GreenKeeper App and advanced machine learning models within GreenKeeper CIS helps to interpret the data. For brevity, I’ll more thoroughly describe this system in an upcoming blog post.

The Pitch

GPS-enabled sprayer can dramatically improve management efficiency for turfgrass managers. There is a clear return on investment, especially when the hardware is paired with software like GreenKeeper CIS. Here’s a recap of the ways the technology has helped me become more efficient at Jim Ager Memorial Jr. GC:

- Simplify Applications: Ability to spray at night before irrigation cycles with confidence that there isn’t excessive over-spray or skips. We spray at 3.5 to 7 MPH to further increase application productivity/efficiency.

- Save Product: Individual nozzle control paired with the ability to edit course boundaries in GreenKeeper CIS has allow me to reduce product use by 10-25% depending on the area – 15,000 to 25,000 square feet of savings).

- Minimize Collar Decline: Prevent over-spray of PGRs on collars and green surrounds. Reduce the risk of over-regulation which can weaken turf to stress and traffic.

- Target Pests: Past application maps/records and on-course scouting allows me to precisely treat pests. Save produce, get improved control, and avoid potential for off-target damage or herbicide phytotoxicity.

- Sensors Aid Scouting: There are new technologies that have the ability to identify plant stress and even locate pests. Pair these sensors with machine-learning algorithms and GreenKeeper CIS can help create prescription maps to spot treat pesticides, fertilizers and wetting agents.

Sign up for GreenKeeper App at GreenKeeperApp.com